Fabric Building Insulation:

When considering coverall fabric buildings for agricultural, industrial, commercial applications, or any other industry, insulation might not be the first feature that comes to mind. But, can you insultate a fabric building ?

However, with modern advances in technology, Fabric Building Insulation has become a viable and highly beneficial option. Here, we’ll explore why insulating a fabric building is worth considering, what options are available, and the key advantages insulation can offer for different applications.

Why choose Fabric Building Insulation?

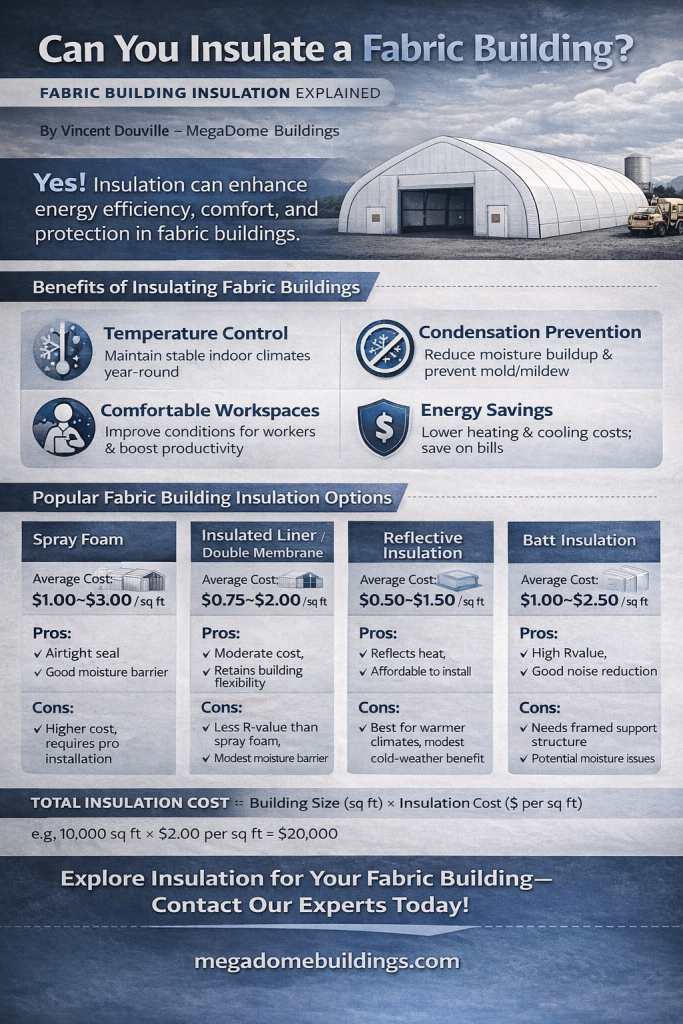

Temperature Control: For fabric structures located in climates with extreme temperatures, insulation can significantly stabilize indoor temperatures. This helps reduce heating costs during colder months and keeps the space cooler in warmer months, making it more comfortable and energy-efficient.

Condensation Prevention: Fabric Building Insulation can reduce condensation by creating a barrier between different temperature zones. This is particularly important in fabric buildings used for storage or housing livestock, where moisture build-up can cause rust, mold, and mildew, potentially damaging valuable equipment or harming animals’ health.

Improved Working Environment: If the fabric building is used as a workspace, insulated walls and roofs can provide a more consistent and comfortable environment for employees or occupants, which can improve productivity and morale.

Energy Savings: Without insulation, heating and cooling a fabric building can become costly, especially if the structure is large. Fabric Building Insulation allows for more effective climate control, reducing the demand on HVAC systems and leading to substantial energy savings over time.

What Are My Options for Insulating a Fabric Building?

There are several Fabric Building Insulation solutions tailored to fabric buildings, each with its own set of benefits and applications. Choosing the right insulation depends on factors such as climate, building use, and budget. Here are some of the most common options:

Spray Foam Insulation

Spray foam insulation is an increasingly popular choice for fabric buildings due to its ease of application and excellent insulating properties. It creates a continuous layer of insulation that helps with energy efficiency and minimizes air leaks.- Pros: Easy to apply, good for tight spaces, provides an air-tight seal.

- Cons: Can be costly and requires a skilled professional to apply correctly.

Insulated Liners or Double Membrane Systems

These systems involve placing an insulated liner within the fabric structure. Some designs use a double-membrane system, where two fabric layers are separated by an insulating material. This can significantly improve thermal retention while maintaining the building’s flexibility.- Pros: Maintains the flexibility of the fabric, good for creating temperature-controlled environments, relatively low cost.

- Cons: Limited insulation performance compared to other options.

Reflective Insulation

Reflective insulation, also known as radiant barrier insulation, works by reflecting radiant heat rather than absorbing it. It is generally a good solution for fabric buildings in hot climates where cooling is a priority, as it can help keep the interior cool by reflecting solar energy.- Pros: Affordable, easy to install, good for warm climates.

- Cons: Not as effective in extremely cold climates; less effective in heat retention.

Batt Insulation

Similar to traditional wall insulation, batt insulation can be installed in certain fabric building designs, especially where there are framed walls or other support structures. This method is best suited for fabric structures that have a semi-permanent or permanent installation.- Pros: Provides excellent thermal insulation, suitable for long-term applications.

- Cons: Requires a stable structure for installation, higher cost, and potential moisture management issues.

Advantages of Fabric Building Insulation

Choosing a Fabric Building Insulation comes with multiple benefits that go beyond simple temperature control. Here are some advantages to consider:

Enhanced Climate Control

Insulation allows for more consistent temperatures within the fabric building, which is essential for certain applications like agriculture, animal welfare, or crop storage. It also improves the building’s adaptability for year-round use, making it suitable for both summer and winter operations.Increased Durability of Stored Goods and Equipment

For fabric buildings used for storage, insulation helps create an environment that protects equipment, machinery, or materials from extreme temperatures especially for the mining industry. Consistent interior conditions prevent materials from warping, cracking, or degrading, reducing wear and tear and extending the lifespan of stored goods.Cost Savings and Energy Efficiency

Fabric Building Insulation can dramatically reduce heating and cooling costs. By helping to keep warm air in during the winter and hot air out during the summer, insulated fabric buildings reduce the workload on HVAC systems, leading to lower utility bills and fewer repairs. This benefit is particularly significant for large structures where climate control is essential.Sound Insulation

Some insulation materials, particularly spray foam and batt insulation, offer sound-dampening properties. This can be an added advantage in applications where noise control is beneficial, such as manufacturing industry, event spaces, animal housing, or facilities near busy areas.Condensation Control

Insulation helps regulate the temperature of the building surfaces, which in turn minimizes condensation. This is especially important in structures housing animals or valuable equipment. By reducing moisture build-up, insulation helps to prevent mold and mildew, which can degrade materials over time and pose health risks.Comfort for People

Insulated fabric buildings provide a stable, comfortable environment that can be essential for workspaces. Keeping indoor temperatures consistent makes the space more pleasant for people working or using the facility, improving both welfare and productivity.

Spray Foam Insulation

- Cost: Approximately $1.00 to $3.00 per square foot for a basic application, with thicker applications costing more.

- Considerations: Spray foam typically costs more upfront but provides excellent insulation and moisture protection. This can be cost-effective in the long run due to energy savings and reduced maintenance needs.

Insulated Liners or Double Membrane Systems

- Cost: Approximately $0.75 to $2.00 per square foot, depending on the thickness of the insulation layer and any additional features like reflective barriers.

- Considerations: This is a popular option for larger fabric buildings due to its affordability and ease of installation. It offers moderate insulation, suitable for many agricultural and storage needs.

Reflective Insulation

- Cost: Around $0.50 to $1.50 per square foot.

- Considerations: Reflective insulation is generally one of the most affordable options, making it ideal for buildings in warmer climates where heat reflection is prioritized over heat retention.

Batt Insulation

- Cost: Approximately $1.00 to $2.50 per square foot.

- Considerations: Batt insulation requires more structural support and is typically used in more permanent fabric buildings or those with framed walls. It is highly effective for thermal insulation but may require additional moisture control measures in humid environments.

Fabric Building Insulation Total Cost

To calculate the total cost of insulating a fabric building, multiply the area of the building (square footage) by the insulation type’s average cost per square foot. For instance, a building measuring 10,000 square feet insulated with spray foam at $2.00 per square foot would cost around $20,000 for insulation alone.

Adding insulation is an investment, but by reducing energy costs and extending the building’s lifespan, insulation can help recoup these costs over time through lower heating and cooling expenses, reduced maintenance, and protection of stored goods or animals.

Final Thoughts

While fabric buildings are inherently flexible and cost-effective, adding insulation can transform these versatile structures into fully climate-controlled spaces suitable for a broader range of applications. Insulating your fabric building isn’t just about comfort—it can protect valuable assets, improve energy efficiency, and increase your building’s longevity.

If you’re considering a fabric building solution, take some time to evaluate your Fabric Building Insulation options based on your specific needs. Whether you’re storing temperature-sensitive materials, creating a comfortable workspace, or housing animals, insulation can help optimize the environment inside your fabric building, ensuring you get the most out of your investment.