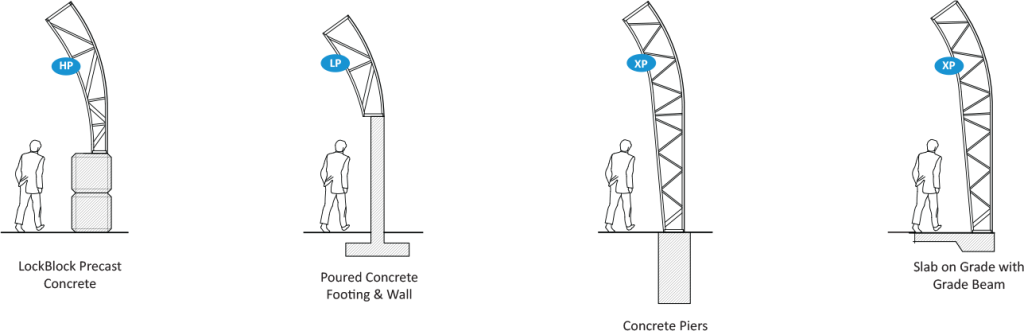

Choosing the Right Foundation for Your Fabric Building

When planning a tension fabric structure, one of the most important decisions you’ll make is choosing the right foundation. Fabric buildings foundations are not one-size-fits-all, their performance, durability, and cost-efficiency depend largely on the foundation system you select.

Selecting the right foundation is not just a structural decision, it’s also a strategic one. The foundation supports the entire weight and tension of the structure and plays a key role in wind and snow load resistance. It must also meet local building codes and adapt to your operational environment.

Let’s explore the most common fabric buildings foundations types and applications in greater detail.

Fabric buildings foundations depend on several factors, including soil conditions, intended use, mobility, and budget. Below, we explore the most common foundation options used for fabric buildings.

Shallow Floating Foundation / Strip Footing

This is one of the most common and economical fabric buildings foundations. It uses continuous concrete footings beneath the sidewalls to distribute the load across a broader area, making it ideal for compacted soil and lighter structures.

Best for: Temporary or seasonal agricultural structures, storage buildings, and workshops.

Deep Foundation

For poor soil conditions or heavy-load structures, deep Fabric Buildings Foundations use piles or caissons driven into the ground to reach stable layers. These are more complex but offer unmatched stability.

Best for: Permanent installations on unstable or flood-prone sites.

Concrete Slab Foundation

A poured concrete slab provides a clean, level surface ideal for equipment-heavy or people-centric applications. While it involves a larger upfront investment, it offers a strong, permanent solution that minimizes dust and simplifies interior maintenance.

Best for: Workshops, garages, aircraft hangars, processing facilities.

Concrete Block Foundation

Concrete blocks are one of the most popular options. They provide excellent stability and height clearance for bulk storage or machinery access. Blocks can be precast or poured on-site and are ideal for temporary or permanent installations. Their modular nature also makes them well-suited for operations that may require future relocation or expansion.

Best for: Agricultural storage, sand and salt bunkers, composting, waste transfer facilities.

Grade Beam / Concrete Beam on Soil

Grade beams sit on the surface or shallow footings and link anchoring points, distributing structural loads evenly. A great middle ground between shallow and deep fabric buildings foundations.

Best for: Semi-permanent buildings in areas with stable soil.

Round Concrete Pier Foundation

For applications that require flexibility and speed, fabric buildings can be mounted on steel rails or concrete piers. These options provide a cost-effective alternative to full abric buildings foundations, especially for smaller or modular buildings.

Best for: Equipment storage, mobile operations, remote construction staging.

Concrete Beam Foundation / Longrines

These horizontal beams rest on piers or soil to provide linear support and simplify the installation process. They are ideal for large modular fabric structures.

Best for: Industrial applications or variable ground conditions.

Why the Right Foundation Matters

Investing in the proper fabric buildings foundations ensures structural integrity, protects your investment, and supports your building’s long-term performance. Whether you’re building for agricultural, commercial, or industrial use, Harnois offers engineered fabric buildings foundations tailored to your specific project needs.

Not sure which fabric buildings foundations is right for you?

Contact our team for a custom recommendation based on your site, structure type, and usage goals.

Site Conditions and Engineering Requirements

Soil composition, drainage, climate, and building load all influence the best choice of fabric buildings foundations. For example, heavy snow regions may require deeper footings, while flood-prone areas might benefit from elevated pier foundations. Every MegaDome project is reviewed by in-house engineers to ensure code compliance and long-term structural integrity.

Integrating the Right Foundation with Your Project Goals

Whether you’re planning a coverall building for municipal salt storage, a composting facility, or a livestock shelter, choosing the proper foundation is key to maximizing durability and efficiency. At MegaDome, we tailor every solution, including the foundation, to your operational goals, budget, and site realities.

What Are Fabric Buildings?

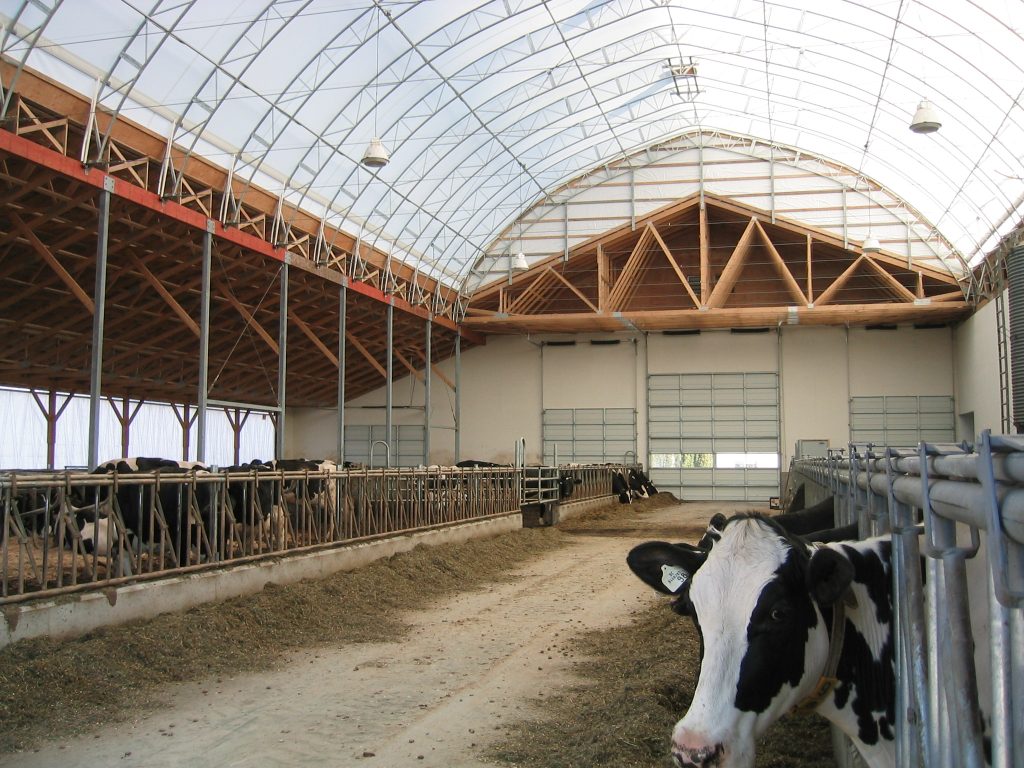

MegaDome Coverall Buildings are modern, cost-effective structures made with a steel truss frame and a durable, tensioned fabric membrane. They offer a flexible, long-lasting alternative to traditional wood or metal buildings and are ideal for agricultural, industrial, and municipal applications.

At MegaDome®, our fabric buildings are engineered and manufactured in Canada to handle even the harshest environments. Our steel truss frames, the backbone of every structure, are available in two roof profiles: a classic peaked roof or an elegant round profile. These options allow you to choose the shape that best fits your operational needs.

Key Features & Benefits:

- Available with peaked or arched steel truss frames

- Double truss

- Lower cost per square foot (starting at $15/sqft)

- 15-year structural warranty

- Customizable sizes and layouts

- Fast installation and easy relocation

- Naturally bright interiors with daylight-diffusing fabric

- Designed for durability and minimal maintenance

- 7 types of Fabric Buildings Foundations

Discover how MegaDome® Coverall Buildings deliver the strength of steel and the efficiency of fabric, engineered to perform, built to last.

Potential Uses of Fabric Covered Buildings

MegaDome® Coverall Buildings offer exceptional versatility across a wide range of industries. In agriculture, they are commonly used for equipment and machinery storage, hay storage, grain storage, livestock housing, and horse riding arenas. Their spacious interiors and natural light make them ideal for maintaining healthy animals and efficient operations.

In the industrial sector, fabric structures serve as warehouses, bulk material storage facilities, maintenance shops, and even remote site shelters, thanks to their rapid installation and portability.

Municipalities and government organizations use fabric buildings for public works equipment storage, recycling centers, emergency response shelters, and fleet garages. Their cost-efficiency and durability make them a smart choice for year-round utility. Commercial and institutional applications include event venues, sports facilities, industrial storage, and aviation hangars, offering scalable space with minimal maintenance.

With their engineered steel truss frames, available in both peaked and arch profiles, and starting at just $15/sqft, MegaDome® Coverall Buildings provide a reliable, adaptable, and long-lasting solution for nearly any environment or operational need.

Benefits of Coverall Fabric Buildings

MegaDome® Coverall Buildings offer a unique combination of strength, flexibility, and efficiency, making them an excellent alternative to traditional structures. One of the most significant benefits is their cost-effectiveness, with prices starting as low as $15 per square foot, fabric buildings provide large, functional spaces at a fraction of the cost of conventional construction.

These buildings are designed for rapid installation, allowing you to have a fully operational facility in weeks instead of months. Their modular design also allows for easy expansion, relocation, or reconfiguration as your needs evolve.

Another significant advantage is the natural light provided by the translucent fabric cladding. This reduces the need for artificial lighting, lowers energy costs, and creates a more comfortable and productive environment for both people and animals. Additionally, fabric buildings are naturally energy-efficient, often maintaining interior temperatures that are cooler in summer and warmer in winter, without relying on active climate control systems.

Built with galvanized steel trusses and tear-resistant polyethylene fabric, MegaDome® structures are engineered to withstand harsh weather conditions, including heavy snow, high winds, and extreme temperatures. Optional coatings, such as epoxy, can further enhance corrosion resistance in demanding applications, including salt storage and marine environments.

Whether you’re in agriculture, industry, or the public sector, fabric buildings offer long-term durability, low maintenance, and superior adaptability, making them an innovative and sustainable choice for a wide range of applications.