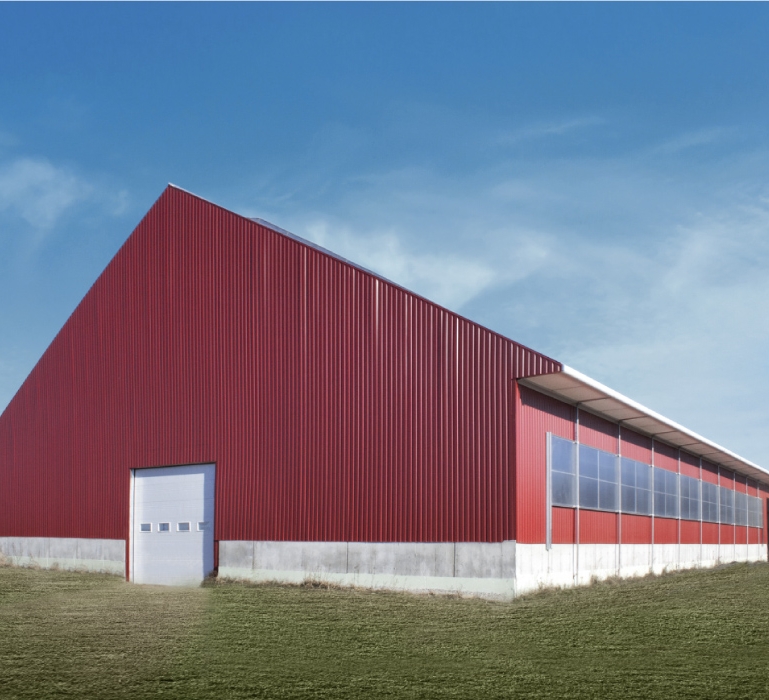

Leader in cover all turnkey fabric buildings structures

MegaDome offers a wide range of models and options, thus allowing personalization to a variety of uses thanks to different dimensions, door choices, and ventilation systems

Moreover, designed to withstand high snow and wind loads, our cover-all fabric buildings are constructed from high-quality materials, ensuring durability and superior weather resistance, thereby making them a reliable investment.

Additionally, the structure and fabric used are low-maintenance, which reduces maintenance costs and minimizes the need for frequent repairs, ultimately contributing to a positive return on investment.

Our Cover All Buildings

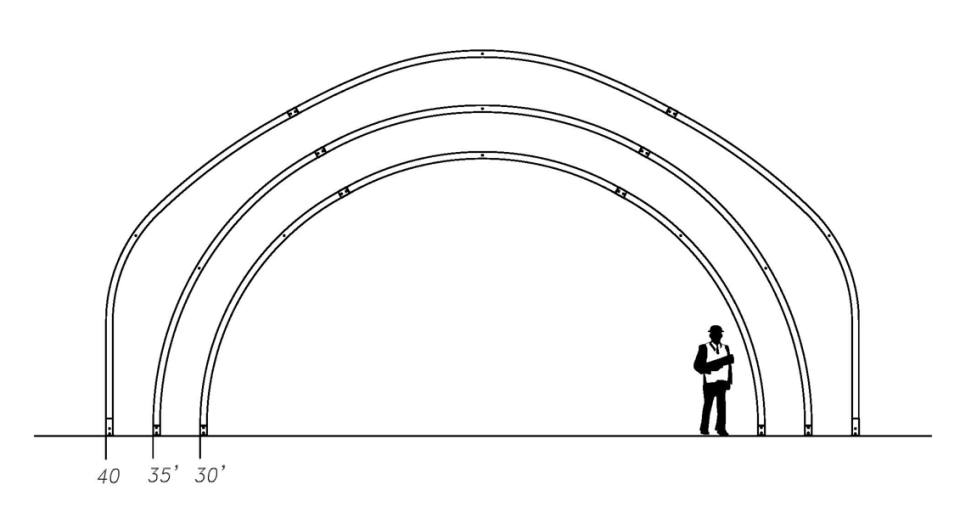

MegaDome EZ

Quick and easy installation.

30 or 40 feet wide

This model boasts a dome-like architecture, characterized by a semi-circular, arched roof. This design is exceptionally robust, allowing for uniform weight distribution, which contributes to its stability and effectiveness. Its seamless, angle-free shape encompasses a vast area, free from any internal support pillars. Moreover, the arch-inspired construction efficiently repels rain and snow.

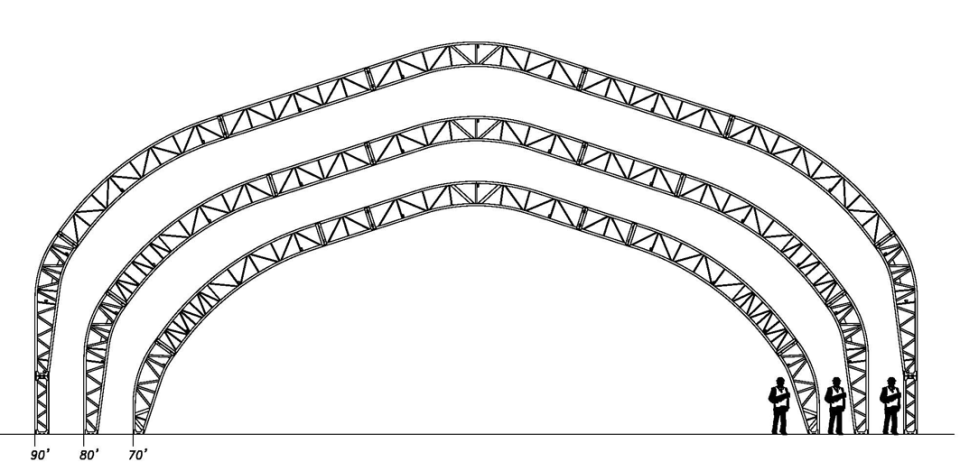

MegaDome DB

Our best-selling building series.

33 to 160 feet wide

The DB profile is very popular with our customers as the elongated lower truss section ads an extra 6’ of interior height and side clearance.

This makes it an ideal selection for high-capacity vertical storage such as warehouse racking, or pallet storage, without the added cost of a high support wall.

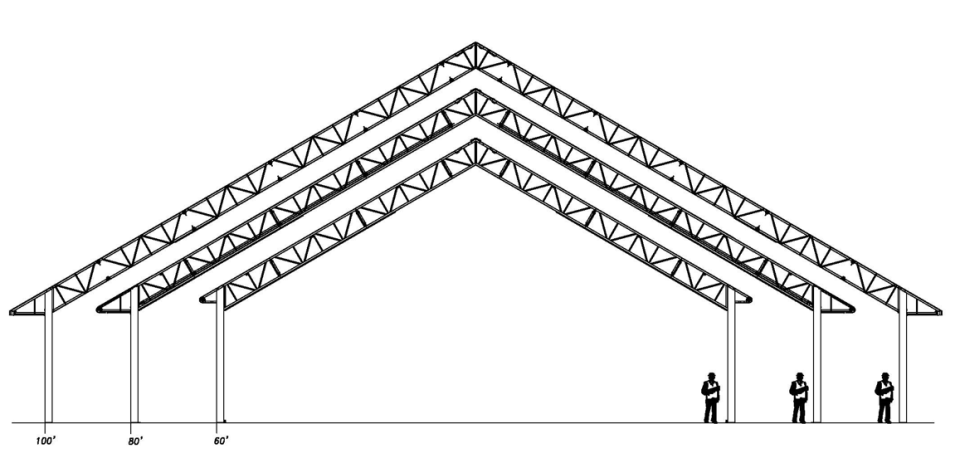

MegaDome AR

Pinnacle of Fabric Building Innovation

60 to 100 feet wide

The AR series is meticulously engineered to cater to precise industrial, commercial, and agricultural needs, offering a bespoke solution for every project. This series stands out by incorporating a high level of automation for enhanced efficiency. These enduring fabric structures merge the pioneering MegaDome® design with all the advantages of traditional buildings, providing a modern, automated alternative to conventional beef barns.

One-stop solution to store and protect

Discover how our coverall fabric buildings are used in your sector. Our expansive fabric building solutions serve as versatile solutions for storage, animal shelter across a wide range of sectors including agriculture, industry, residential, retail, and commercial. These structures are perfectly suited for both permanent and temporary setups, offering maximum ease, comfort, and functionality. Regardless of the industry, our fabric-covered facilities are the perfect choice for all your indoor space extension requirements

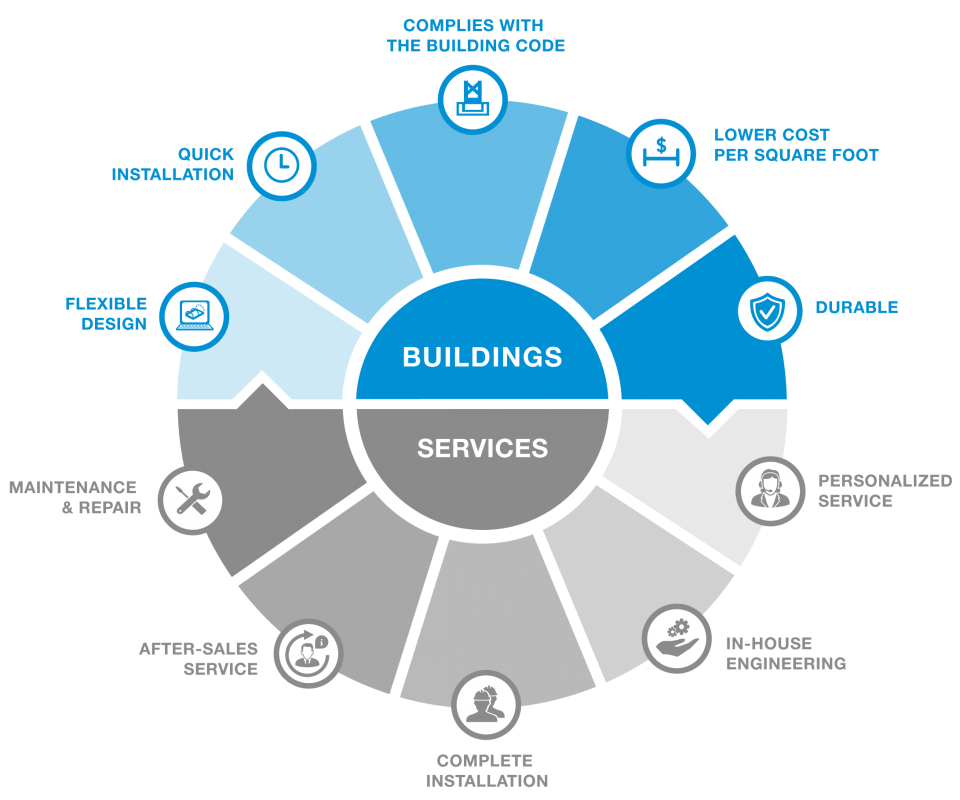

From Design to Repairs

We provide a complete 360° service, from design to final repairs, ensuring quality and sustainability at every step. Our team offers personalized design, state-of-the-art production, and flexible customization, alongside dedicated support and eco-conscious practices. We’re not just making tension fabric buildings; we’re crafting lasting partnerships and sustainable solutions to meet your every need.

Become a distributor

Add MegaDomeMD fabric buildings to your product offer to better meet the needs of your customers.